Endoscopes are a standard device in gastrointestinal medicine, used by surgeons to noninvasively see and take biopsies from tissues along the entire digestive tract. However, endoscopes themselves amount to hollow tubes with a camera and light attached, through which different instruments are threaded to the procedure site, and are rigid and not very maneuverable. Two add-on technologies being developed by the Wyss Institute aim to make endoscopes better able to interact with human tissue.

A hybrid rigid-soft robotic arm combines soft robotic technologies with origami-inspired rigid structures to generate forces sufficient to manipulate tissue while minimizing injury. The arm lies flat along the outside of the endoscope until the reaches the site of the procedure, then pops up using pressurized water from a fluidic line that runs the length of the endoscope. It is equipped with a suction cup inspired by those found on octopus tentacles so it can stabilize tissue to be biopsied and perform other functions. Additionally, a sensor can be integrated that allows a surgeon to know how much pressure is being applied and make adjustments to prevent damage, as well as where the robotic arm is in the body. The arm is attached to the endoscope as a “cap” that can be manufactured in bulk and disposed after each surgery.

The ability to seamlessly integrate gentle yet effective actuation into millimeter-scale deployable mechanisms fits naturally with a host of surgical procedures. We are focused on some of the more challenging endoscopic techniques where tool dexterity and sensor feedback are at a premium and can potentially make the difference between success and failure.

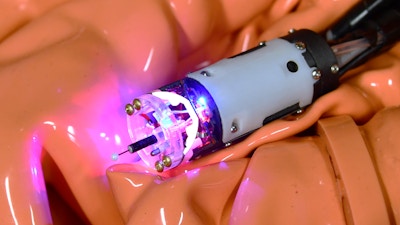

EndoMODRA (Endoscopic Module for On-Demand Robotic Assistance), another endoscope add-on device, aims to integrate the increased dexterity and control of advanced robotic systems into a low-cost, single use module that attaches to the end of an endoscope and is equipped with on-board actuation and sensing capabilities. The system engages with any tool passed through the endoscope working port to provide precision robotic control of the tool’s lateral motion while allowing an endoscopist to maintain full control over all other functions already available, thereby facilitating otherwise technically challenging movements and allowing for seamless switching between manual control and robotic assistance. The device includes shape-memory alloy actuators and forced-convection fluid cooling that speeds up its actuation from ~100 seconds to ~1 second. Hall-effect sensors detect the tool’s lateral angle, and an adaptive controller can control the angle with less than 1° of error, laying the groundwork for automated robotic tissue dissection on an on-demand basis.

These technologies are undergoing further development.