Soft robots, similar to living organisms, are made from compliant materials that allow them great flexibility and adaptability for tasks at the human-robot interface and elsewhere. To enable soft robotic missions in different industrial, exploratory, and medical settings, engineers are trying to equip them with artificial muscles that could enable them to move smoothly, efficiently and safely without disrupting their soft properties. However, the development of easy-to-operate high-performance artificial muscles that can perform complex motions and be fabricated at low costs has remained challenging.

Researchers led by Robert Wood at the Wyss Institute and the Harvard John A. Paulson School of Engineering and Applied Sciences, and Daniela Rus at the Massachusetts Institute of Technology’s Computer Science and Artificial Intelligence Laboratory have developed a solution to this challenge by creating fluid-driven origami-inspired artificial muscles (FOAMs) that allow soft robots to lift objects that are up to 1,000 times their own weight using only air or water pressure.

Artificial muscle-like actuators are one of the most important grand challenges in all of engineering. Now that we have created actuators with properties similar to natural muscle, we can imagine building almost any robot for almost any task.

The FOAM concept integrates three basic components – a compressible skeleton, a flexible skin, and a fluid medium – within a mechanical framework that defines their interactions. The skeleton can be made in a variety of shapes using various materials, such as a metal coil or a sheet of plastic pre-folded into a particular pattern. Surrounded by air or fluid within a plastic or textile skin, the application of a vacuum reversibly reconfigures the skeleton, similar to origami that fold along a particular path into their final shape, allowing FOAMs to carry out motions along multiple axes, such as contraction, bending and torsion motions in a safe and powerful fashion. They are able to contract over 90% of their initial lengths and generate stresses that can exceed those of natural muscles. In addition, their relatively simple architecture opens the door to a rapid design and low-cost fabrication process.

FOAMs could be developed for soft robots at many scales and applications, ranging from miniature medical devices for delicate surgeries and certain therapies, to wearable robotic exoskeletons, to large deployable structures for oceanic and space exploration.

1/4 The FOAM concept can be applied to artificial muscles made at different scales and with different geometries and materials to enable a variety of future applications. Credit: Wyss Institute at Harvard University

2/4 The FOAM concept can be applied to artificial muscles made at different scales and with different geometries and materials to enable a variety of future applications. Credit: Wyss Institute at Harvard University

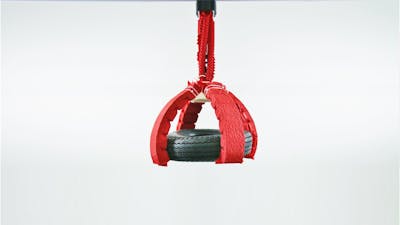

3/4 Origami-inspired artificial muscles are capable of lifting up to 1,000 times their own weight, simply by applying air or water pressure. Credit: Wyss Institute at Harvard University

4/4 The FOAM concept can be applied to artificial muscles made at different scales and with different geometries and materials to enable a variety of future applications. Credit: Wyss Institute at Harvard University