Just like pores in living organisms that control the absorption and excretion of fluids, gases and solids in response to their environments, flow-gating membranes have proved very useful for many mechanical systems, such as gas and liquid separators, dialysis machines, or open heart bypass pumps. But conventional approaches to create synthetic “gated pores” within those membranes have resulted in openings that are fixed in geometry, with properties defined by the filter membrane material. In addition, large-scale filtration operations to provide drinking water, process wastewater, manufacture foods and beverages and many other industrial applications consume a significant amount of electrical power. To make things worse, these systems often get clogged during use due to accumulation of small particles and fouling by sticky materials, and become less energy efficient as the filter blockage increases with use.

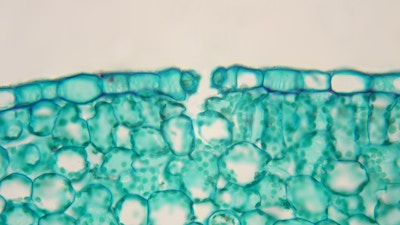

Liquid Gated Membranes (LGMs) mimic nature’s use of liquid-filled pores to control the movement of liquids, gases and particles through filters at the lowest possible energy input. Almost any membrane and existing filtration system can be converted to an LGM by the addition of a chemically and energetically matched liquid that acts as a reversible gate, filling and sealing pores in the closed state, while creating non-fouling, liquid-lined pores tuned to pass specific liquids or gases in the open state. The use of fluid enables dynamic and precise control of multiphase (for example, gas–water–oil) separations that are common in industrial processing, with the liquid lining providing the additional benefit of sustained antifouling performance.

Our new approach harnesses dynamic and responsive control over a highly sensitive and reversible gating mechanism, which we can now apply toward many diverse applications.

The LGM technology can be applied to a variety of pore sizes (nano to micro filters), membrane materials (polymers to ceramic and metallic) and filter formats (hollow fiber and flat sheets) and can provide significant energy savings over time. These characteristics make LGMs attractive for a wide range of applications including municipal water treatment, industrial separation processes, and biomedical filter applications.

The LGM technology is available for licensing in all fields.