Project 1985, launched by Harvard and 1955 Capital, is developing the Wyss’ pop-up manufacturing technology for minimally invasive robot-assisted surgery

The Problem

Surgical robots have revolutionized procedures for patients around the world, making them more precise and less invasive than earlier tools. But most surgical robots are massive devices that can take up an entire room and cost millions of dollars. And the surgical tools themselves that enter the patient’s body are currently too large to access certain organs and tissues.

Our Solution

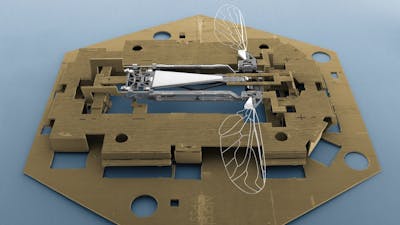

Researchers at the Wyss Institute and Harvard’s John A. Paulson School of Engineering and Applied Sciences (SEAS) have created a new micro-manufacturing technique called Pop-Up MEMS, inspired by children’s pop-up books and origami. It enables micro-scale robots to be quickly and cheaply manufactured at scale, reducing the labor and time required and expanding the potential of robot-assisted surgeries.

Product Journey

Originally funded by a National Science Foundation grant and the Wyss Institute’s Bioinspired Robotics Platform, Pop-Up MEMS was developed by Wyss Associate Faculty member Rob Wood, Ph.D. His lab’s blue-skies exploration of the challenge of manufacturing tiny robots resulted in the RoboBee, which first took flight in 2012. Through successive iterations of the manufacturing process that transformed it from painstaking manual work to layering and folding, the team endowed their tiny flying robot with more skills at the micro-scale, including perching and swimming.

The team also used this approach to develop HAMR, a cockroach-inspired crawling microrobot; milliDelta, a millimeter-scale delta robot; and a microrobotic laser-steering device for minimally invasive surgeries.

The microrobots embarked on their path toward commercialization when SEAS Dean Frank Doyle introduced alumnus and founder of venture firm 1955 Capital, Andrew Chung, to Wood. After exploring Wood’s varied research portfolio, Chung recognized an opportunity to help commercialize his work for broader impact.

It was apparent to Chung that Wood’s pop-up fabrication techniques could shrink surgical robots dramatically, making them up to 90% smaller in size, opening up much more of the human body to robotic surgery procedures that are currently possible. He assembled a team of colleagues from 1955 Capital with experience in venture capital, biomedical engineering, and surgical robotics, and Project 1985 was formed in 2022.

Impact

Project 1985 is initially exploring potential applications in several application areas that might have promise, including neurosurgery, urology, and lung surgery.