A Band-Aid® adhesive bandage is an effective treatment for stopping external bleeding from skin wounds, but an equally viable option for internal bleeding does not yet exist. Surgical glues are often used inside the body instead of traditional wound closure techniques like stitches, staples, and clips because they reduce the patient’s time in the hospital and lower the risk of secondary injury/damage at the wound site. An effective surgical glue needs to be strong, flexible, non-toxic, and able to accommodate movement, yet there are no adhesives currently available that have all of those properties. Researchers at the Wyss Institute have developed a new super-strong hydrogel adhesive inspired by the glue secreted by a common slug that is biocompatible, flexible, and can stick to dynamically moving tissues even in the presence of blood.

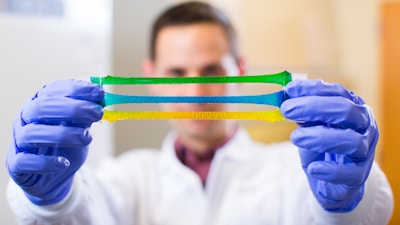

The hydrogel itself is a hybrid of two different types of polymers: a seaweed extract called alginate that is used to thicken food, and polyacrylamide, which is the main material in soft contact lenses. When these relatively weak polymers become entangled with each other, they create a molecular network that demonstrates unprecedented toughness and resilience for hydrogel materials – on par with the body’s natural cartilage. When combined with an adhesive layer containing positively-charged polymer molecules (chitosan), the resulting hybrid material is able to bind to tissues stronger than any other available adhesive, stretch up to 20 times its initial length, and attach to wet tissue surfaces undergoing dynamic movement (e.g., a beating heart).

Studies of the hydrogel adhesive demonstrated that it is capable of withstanding three times the amount of tension that disrupts the best current medical adhesives, maintaining its stability and adhesion when implanted into rats for two weeks, and sealing a hole in a pig heart that was subjected to tens of thousands of cycles of pumping. Additionally, it caused no tissue damage or adhesions to surrounding tissues when applied to a liver hemorrhage in mice.

The hydrogel adhesive has numerous potential applications in the medical field, either as a patch that can be cut to desired sizes and applied to many tissues including bone, cartilage, tendon, or pleura, or as an injectable solution for deeper injuries. It can also be used to attach medical devices to their target structures, such as an actuator to support heart function. While the current iteration is designed to be a permanent structure, it could be made to biodegrade over time as the body heals from injury.

A newer version of the adhesive has thermoreactive properties that cause it to contract when heated to body temperature, helping to dynamically close wounds and prevent bacterial growth during healing.