The Problem

In more than four million people each year, heart valves fail for different reasons, including birth defects, age-related deteriorations and infections. Currently, doctors can replace damaged heart valves with synthetic or transplanted ones, but these also wear down over time and need to be replaced. This problem is especially difficult for children, whose bodies are still growing and who often need multiple, invasive heart valve replacement surgeries.

Our Solution

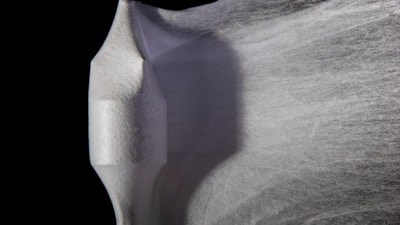

Researchers at the Wyss Institute, the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), and the University of Zurich’s Wyss Center for Regenerative Medicine have developed a nanofiber fabrication technique that is able to rapidly manufacture customizable heart valves with regenerative and growth potential. The technique, called focused rotary jet spinning (FRJS), extrudes a polymer solution into long fibers that wrap themselves around a heart-valve-shaped mandrel – similar to how a cotton candy machine spins sugar crystals into fluffy clouds wrapped around a paper cone. FRJS can create a valve in less than ten minutes, is customizable to different age groups and conditions, and is much more cost-effective than other manufacturing techniques.

Product Journey

This new type of heart valve can be implanted with minimally invasive surgical procedures applicable to all age groups. In preclinical studies in sheep, they functioned properly immediately after implantation and were able to recruit cells that can regenerate new heart-like tissue over time. The team has developed two iterations of these valves – the JetValve and the FibraValve, and is further investigating this platform for the creation of additional heart-related medical devices including other valves, cardiac patches, blood vessels, and regenerated myocardial tissues.

Impact

The team is looking to start long-term preclinical large animal studies, and is seeking partners interested in helping to fund further research.