Delta robots are deployed in many industrial processes, including pick-and-place assemblies, machining, welding, and food packaging. Three individually controlled lightweight arms enable fast and accurate motion of an output platform in three directions. Roboticists have reduced the size of Delta robots for tasks in limited workspaces, but so far, using conventional manufacturing techniques and components, they have not succeeded in shrinking them down to the millimeter scale where they could be useful for entirely different applications.

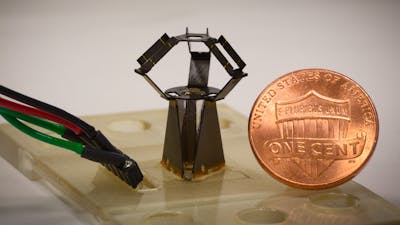

Wyss Institute researchers have used their origami-inspired pop-up Microelectromechanical systems (MEMS) manufacturing technique and high-performance composite materials to design the milliDelta, a 15 mm-by-15 mm-by-20 mm Delta robot.

The physics of scaling told us that bringing down the size of Delta robots would increase their speed and acceleration, and pop-up MEMS manufacturing…seemed an ideal way to attack this problem.

Equipped with piezoelectric actuators, the milliDelta can operate at frequencies that are 15 to 20 times higher than those of other currently available Delta robots, and it can perform tasks with micrometer precision in limited spaces. In addition, its small form factor makes it suitable for integration with existing devices; for example, as a tremor cancelling end effector for micromanipulation or microsurgery. Additional applications for this robot include its use in small-scale pick-and-place processes, such as circuit-board population or cell manipulation.

The milliDelta technology is available for licensing.

Please see also our microrobotics technologies for autonomously flying microrobots (RoboBees) and versatile ambulatory microrobots (HAMRs).