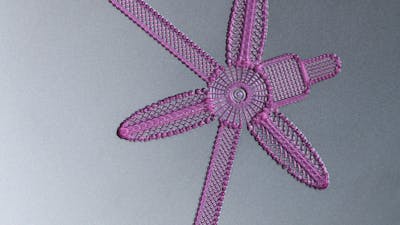

Organisms, such as flowers and plants, have tissue compositions and microstructures creating dynamic morphologies that can shapeshift in response to changes in their environments. Researchers at the Wyss Institute have mimicked a variety of such dynamic shape changes like those performed by tendrils, leaves, and flowers in response to changes in humidity or temperature with innovative 4D-printed hydrogel composites.

By aligning cellulose fibrils that are derived from wood in configurations that are predicted with a proprietary mathematical model in the 4D-printing process, the composite ink encodes anisotropic swelling and stiffness properties that can be patterned along the printing path. With this technology, local swelling behaviors become programmable in water-immersed composites, which as a result produce intricate and highly predictable shape changes. In addition, a variety of hydrogel materials can be used interchangeably resulting in different stimuli-responsive behaviors, while the cellulose fibrils can be replaced with other anisotropic fillers of choice, including conductive fillers. These materials may be used to fabricate medical devices that take on programmed shapes when placed in contact with body fluids, as well as smart textiles, responsive building materials and novel electronic sensors and actuators.